Bidiyo

Gabaɗaya bayanin

Ana amfani da TP-TGXG-200 Na'urar Capping Na atomatik don murƙushe iyakoki akan kwalabe ta atomatik. Ana amfani da shi sosai a abinci, magunguna, masana'antar sinadarai da sauransu. Babu iyaka akan siffa, abu, girman kwalabe na al'ada da iyakoki. Nau'in capping mai ci gaba yana sa TP-TGXG-200 ya dace da saurin jigilar kayayyaki daban-daban. Wannan na'ura da gaske tana da dalilai da yawa, waɗanda ake amfani da su sosai kuma a sauƙaƙe. Kwatanta da nau'in aiki na tsaka-tsaki na gargajiya, TP-TGXG-200 ya fi ƙarfin aiki, ƙara matsawa, kuma yana haifar da ƙarancin lahani ga iyakoki.

Aikace-aikace

Ana iya amfani da na'urar capping na atomatik akan kwalabe tare da ƙugiya a cikin nau'i daban-daban, siffofi da kayan.

A. Girman kwalba

Ya dace da kwalabe tare da diamita 20-120mm da tsayin 60-180mm. Amma ana iya keɓance shi akan girman kwalbar da ya dace fiye da wannan kewayon kuma.

B. Siffar kwalba

Ana iya amfani da injin capping ɗin atomatik akan sifofi daban-daban kamar murabba'in murabba'i ko siffa mai rikitarwa.

C. Kwalban da kayan hula

Ko wane irin filastik gilashi ko karfe, injin capping na atomatik zai iya ɗaukar su duka.

D. Nau'in hula

Na'urar capping na atomatik na iya murƙushe kowane nau'in hular dunƙule, kamar famfo, fesa, ɗigo hula da sauransu.

E. Masana'antu

Injin capping ɗin atomatik na iya haɗawa da kowane nau'ikan masana'antu komai foda, ruwa, layin tattarawa, ko abinci, magani, sunadarai ko kowace masana'anta. A duk inda akwai dunƙule iyakoki, akwai injin capping ɗin atomatik don aiki da shi.

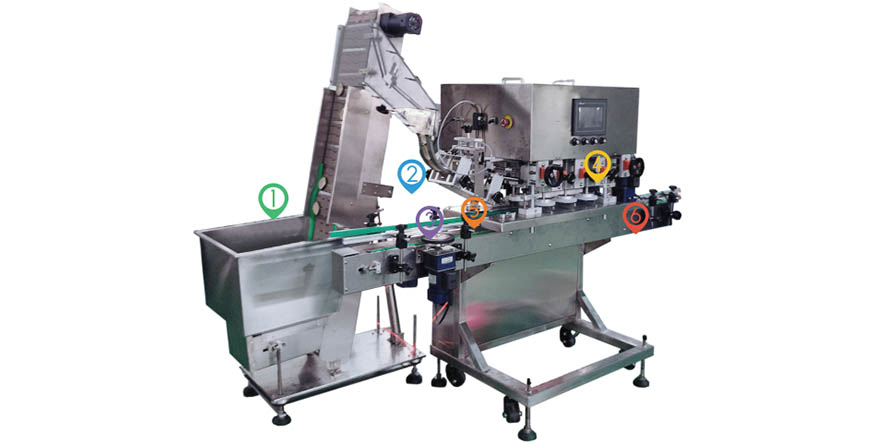

Gina & tsarin aiki

Ya ƙunshi injin capping da mai ciyar da hula.

1. Kafa feeder

2. Sanya hula

3. Mai raba kwalba

4. Kefe da ƙafafu

5. bel din dafe kwalba

6. Belin isar da kwalba

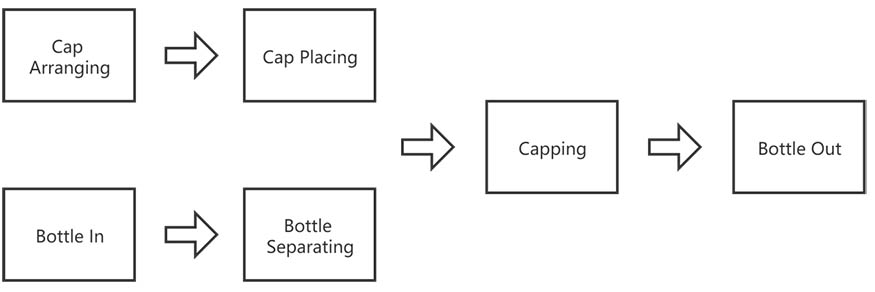

Wadannan suna aiwatar da aiki

Siffofin

An yi amfani da shi sosai a cikin kwalabe da huluna na siffofi da kayan daban-daban.

n PLC&allon allon taɓawa, mai sauƙin aiki.

∎ Aiki mai sauƙi da sauƙin daidaitawa, adana tushen ɗan adam da tsadar lokaci.

■ Babban sauri da daidaitacce, wanda ya dace da kowane nau'in layin tattarawa.

■ Tsayayyen aiki da ingantaccen inganci.

∎ Aikin farawa maɓalli ɗaya yana kawo dacewa da yawa.

∎ Cikakken ƙira yana sa injin ya zama ɗan adam da hankali.

∎ Kyakkyawan rabo akan hangen na'ura, babban matakin ƙira da bayyanar.

■ Jikin inji an yi shi da SUS 304, ya dace da ma'aunin GMP.

Duk sassan tuntuɓar da kwalba da murfi an yi su ne da amincin kayan abinci.

∎ Allon nuni na dijital don nuna girman kwalabe daban-daban, wanda zai dace don canza kwalban (Zaɓi).

■ Na'urar firikwensin gani don cire kwalabe waɗanda kuskure suka rufe (Zaɓi).

n Na'urar ɗagawa don ciyarwa a cikin murfi ta atomatik.

■ Bangaren faɗuwar murfi na iya cire murfi na kuskure (ta hanyar busa iska da auna nauyi).

∎ Belin don danna murfi yana karkata, don haka zai iya daidaita murfi zuwa wurin da ya dace sannan a danna.

Mai hankali

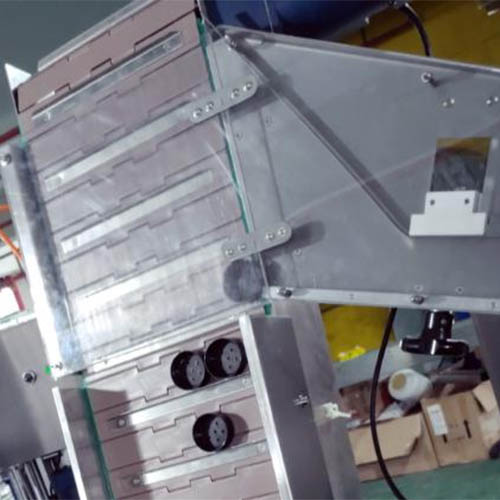

Yi amfani da ƙa'idar ma'auni daban-daban na ma'auni na tsakiya a ɓangarorin biyu na hula, kawai madaidaiciyar hular shugabanci za a iya motsa sama zuwa sama. Tafarkin da ba daidai ba zai faɗi ƙasa ta atomatik.

Bayan na'ura mai ɗaukar kaya ya kawo iyakoki a sama, mai busa ya zagaya cikin titin hula.

Kuskuren firikwensin murfi na iya gano jujjuyawar murfi cikin sauƙi. Kuskuren iyalai na atomatik mai cirewa da firikwensin kwalban, isa ga kyakkyawan tasirin capping

Mai raba kwalabe zai raba kwalabe da juna ta hanyar daidaita saurin motsi na kwalabe a matsayinsa. kwalabe masu zagaye yawanci suna buƙatar mai raba guda ɗaya, kuma kwalabe masu murabba'i suna buƙatar masu raba biyu masu gaba da juna.

Rashin gano na'ura yana sarrafa mai ciyar da hula yana aiki da tsayawa ta atomatik. Akwai na'urori masu auna firikwensin guda biyu a gefe biyu na titin hula, ɗaya don bincika idan waƙar tana cike da iyakoki, ɗayan don bincika idan waƙar ba ta da komai.

Ingantacciyar

Matsakaicin saurin isar kwalabe da mai ciyar da hula na iya kaiwa 100 bpm, wanda ke kawo babban saurin injin don dacewa da layin tattarawa daban-daban.

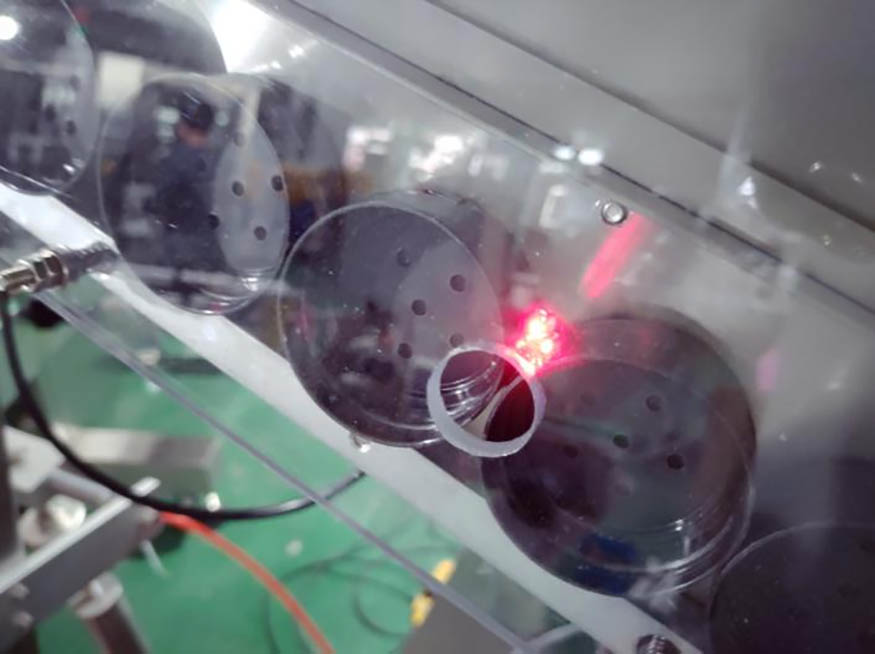

Biyu na ƙafafu uku suna jujjuya iyakoki da sauri. Kowane ɗayan biyun yana da takamaiman aiki. Biyu na farko na iya juyawa baya don yin wahalar sanya iyakoki su kasance a daidai matsayin sa. Amma suna iya yin iyakoki suna juyawa ƙasa don isa wurin da ya dace da sauri tare da ƙafafu na biyu a lokacin da hula ta zama al'ada. Nau'i-nau'i na uku suna daidaita dan kadan don matse hular, don haka saurinsu ya fi jinkiri a tsakanin dukkan ƙafafun.

Dace

Kwatanta tare da daidaita dabaran hannu daga wasu masu kaya, maɓalli ɗaya don ɗagawa ko rage duka na'urar capping ɗin ya fi dacewa.

Ana amfani da maɓalli huɗu daga hagu zuwa dama don daidaita saurin isar da kwalabe, matsar kwalba, hawan hula da rabuwar kwalba. Bugun bugun kira na iya jagorantar mai aiki don isa ga saurin dacewa ga kowane nau'in fakiti cikin sauƙi.

Hannun ƙafafu don canza nisa tsakanin bel ɗin manne kwalban cikin sauƙi. Akwai ƙafafu biyu a ƙarshen biyu na ƙulla bel. Kiran bugun kira yana jagorantar afareta don isa wurin daidai daidai lokacin canza girman kwalban.

Canjawa don daidaita tazara tsakanin ƙafafun cafa da iyakoki. Mafi kusa da nisa, madaidaicin hula zai kasance. Dial yana taimaka wa mai aiki don nemo mafi dacewa tazara mai dacewa.

Aiki mai sauƙi

PLC&allon allon taɓawa tare da shirin aiki mai sauƙi, yana sa aikin ya fi sauƙi kuma mafi inganci.

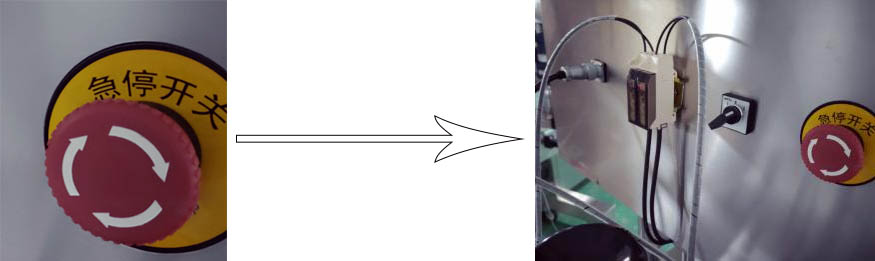

Maɓallin gaggawa don dakatar da injin a lokaci ɗaya a cikin gaggawa, wanda ke kiyaye ma'aikacin tsaro.

| TP-TGXG-200 Bottle Capping Machine | |||

| Iyawa | 50-120 kwalabe / min | Girma | 2100*900*1800mm |

| Diamita na kwalabe | Φ22-120mm (na musamman bisa ga bukata) | Tsawon kwalba | 60-280mm (na musamman bisa ga bukata) |

| Girman murfin | Φ15-120mm | Cikakken nauyi | 350kg |

| Adadin da ya dace | ≥99% | Ƙarfi | 1300W |

| Matrial | Bakin Karfe 304 | Wutar lantarki | 220V / 50-60Hz (ko musamman) |

| A'a. | Suna | Asalin | Alamar |

| 1 | Mai juyawa | Taiwan | Delta |

| 2 | Kariyar tabawa | China | TouchWin |

| 3 | Sensor na gani | Koriya | Masu sarrafa kansu |

| 4 | CPU | US | ATMEL |

| 5 | Chip Interface | US | MEX |

| 6 | Latsa Belt | Shanghai |

|

| 7 | Jerin Motoci | Taiwan | TALIKE/GPG |

| 8 | SS 304 Frame | Shanghai | BaoSteel |

Na'urar capping na atomatik na iya aiki tare da na'ura mai cikawa da na'ura mai lakabi don samar da layin tattarawa.

A. Bottle unscrambler+auger filler+atomatik capping machine+foil sealing machine.

B. Bottle unscrambler+auger filler+atomatik capping machine+foil sealing machine+labeling machine

ACCESSORIES a Akwatin

■ Littafin koyarwa

n Zane na lantarki da zane mai haɗawa

■ Jagoran aiki na aminci

■ Saitin kayan sawa

■ Kayan aikin kulawa

■ Lissafin saiti (asalin, samfuri, ƙayyadaddun bayanai, farashi)

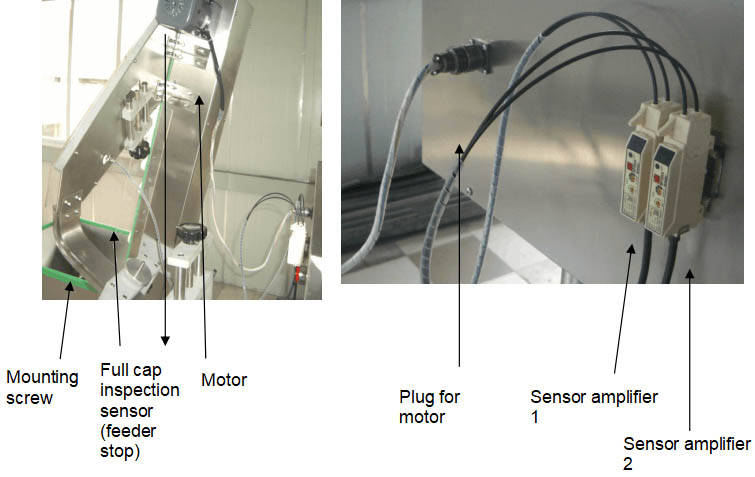

1. Shigar da hula Elevator da hula sanya tsarin.

(1) Shigar da tsari na hula da firikwensin ganowa.

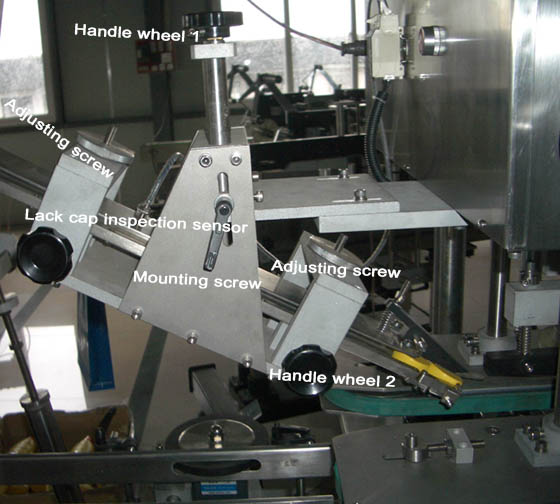

An raba lif da tsarin sakawa kafin jigilar kaya, da fatan za a shigar da tsarin tafiyar tafiya da sanya tsarin a kan injin capping kafin gudanar da injin. Da fatan za a haɗa tsarin kamar yadda aka nuna a cikin hotuna masu zuwa:

Rashin firikwensin dubawa (tasha injin)

a. Haɗa waƙa mai sanya hula da ramp tare da dunƙule hawa.

b. Haɗa wayar motar tare da filogi a gefen dama akan sashin kulawa.

c. Haɗa cikakken firikwensin duba hula tare da firikwensin firikwensin 1.

d. Haɗa firikwensin dubawar rashin hula tare da firikwensin firikwensin 2.

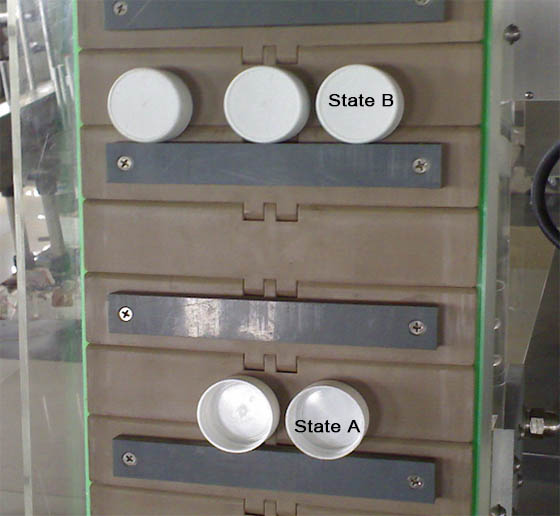

Daidaita kusurwar sarkar hawan hula: An daidaita kusurwar sarkar hawan tafiya bisa ga samfurin samfurin da kuka bayar kafin jigilar kaya. Idan ya zama dole don canza ƙayyadaddun hula (kawai canza girman, canza nau'in hular), da fatan za a daidaita kusurwar sarkar hawan tafiya ta kusurwar daidaitawar dunƙule har sai sarkar kawai zata iya isar da iyakoki waɗanda ke jingina kan sarkar tare da saman gefe. Alamomi kamar haka:

Hul ɗin da ke jihar A daidai take lokacin da sarƙar hawan hawan ke kawo iyakoki sama.

Mafar da ke jihar B za ta faɗo cikin tanki ta atomatik idan sarkar tana cikin kusurwar da ta dace.

(2) Daidaita tsarin zubar da hula (chute)

An riga an saita kusurwar juzu'i da sarari bisa ga samfurin da aka bayar. Yawanci idan babu wani sabon ƙayyadaddun kwalabe ko hula, saitin baya buƙatar daidaitawa. Kuma idan akwai ƙarin bayani dalla-dalla fiye da ƙayyadaddun 1 na kwalban ko hula, abokin ciniki yana buƙatar lissafin abu akan kwangila ko abin da aka makala don tabbatar da masana'antar ta bar isasshen sarari don ƙarin gyare-gyare. Hanyar daidaitawa shine kamar haka:

Daidaita tsayin tsarin sauke hula: Da fatan za a kwance dunƙule mai hawa kafin kunna dabaran hannu 1.

Matsakaicin daidaitawa na iya daidaita tsayin sarari na chute.

Dabaran rikewa 2 (a gefe biyu) na iya daidaita nisa na sarari na chute.

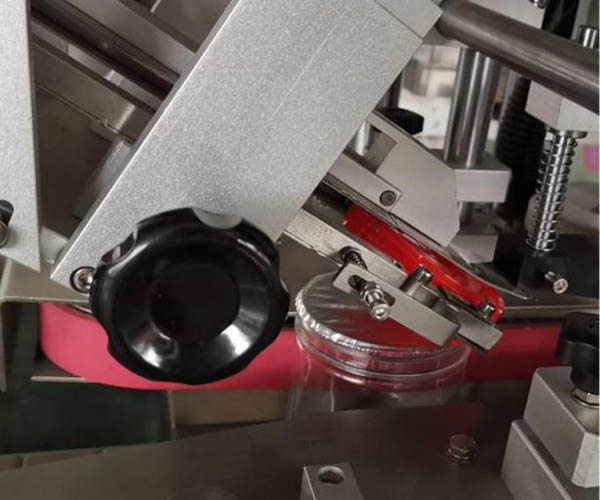

(3) Daidaita sashin latsa hula

Hul ɗin za ta rufe bakin kwalbar daga guntu ta atomatik lokacin da kwalbar ke ciyarwa cikin yankin danna hula. Hakanan za'a iya daidaita sashin danna hula saboda tsayin kwalabe da iyakoki. Zai shafi aikin capping idan matsa lamba akan hular bai dace ba. Idan matsayin ɓangaren latsa hula ya yi tsayi da yawa, aikin latsawa zai yi tasiri. Kuma idan matsayi ya yi ƙasa da ƙasa, hular ko kwalban za ta lalace. Yawanci an daidaita tsayin ɓangaren matsin hula kafin jigilar kaya. Idan mai amfani yana buƙatar daidaita tsayi, hanyar daidaitawa shine kamar haka:

Da fatan za a kwance dunƙule mai hawa kafin daidaita tsayin ɓangaren danna hula.

Akwai wani ɓangaren danna mashin tare da injin don dacewa da ƙaramin kwalban, hanyar canji ana nuna shi a cikin bidiyon.

(4). Daidaita matsin iska don busa hular cikin tsinke.

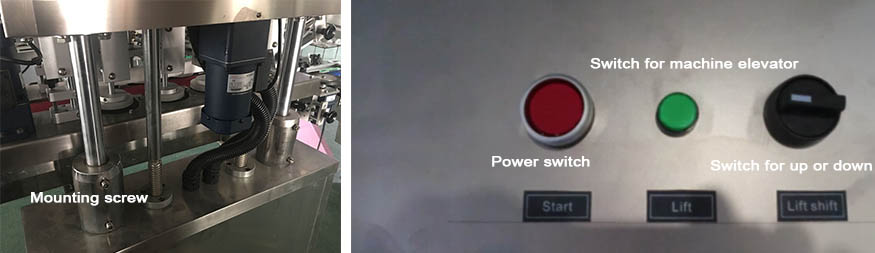

2. Daidaita tsayin manyan sassa gaba ɗaya.

Tsawon manyan sassa kamar tsarin gyaran kwalabe, dabaran ƙwanƙwasa-lastic, ɓangaren matsin hula za a iya daidaita shi gaba ɗaya ta injin lif. Maɓallin sarrafawa na lif na inji yana gefen dama na kwamitin kulawa. Mai amfani yakamata ya kwance dunƙule masu hawa akan ginshiƙan tallafi guda biyu kafin fara lif na inji.

ø yana nufin ƙasa kuma ø yana nufin sama. Don tabbatar da matsayi na ƙafafun juyi ya dace da iyakoki. Da fatan za a kashe wutar elevator kuma a ɗaure dunƙule mai hawa bayan daidaitawa.

Lura: Da fatan za a danna maɓallin ɗagawa (kore) koyaushe har sai an sami matsayi mai kyau. Gudun lif yana sannu a hankali, da fatan za a jira da haƙuri.

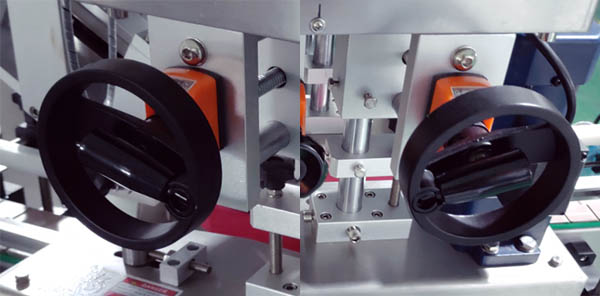

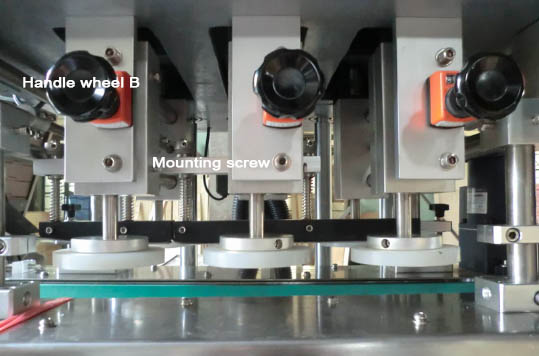

3. Daidaita dabaran juzu'i-lastic (nau'i-nau'i uku na dabaran juyi)

Ana daidaita tsayin dabaran juyi ta injin lif.

An daidaita nisa biyu na dabaran juyi gwargwadon diamita na hula.

Yawanci nisa tsakanin ƙafa biyu shine 2-3mm ƙasa da diamita na hula. Mai aiki na iya daidaita nisa na dabaran juyi ta hannun dabaran B. (kowane dabaran hannu yana iya daidaita dabaran juzu'in dangi).

Da fatan za a kwance dunƙule mai hawa kafin daidaita dabaran hannun B.

4. Daidaita tsarin gyaran kwalban.

Za'a iya daidaita matsayin gyaran kwalabe ta hanyar daidaitawa tsarin gyaran gyare-gyare da haɗin haɗin gwiwa. Idan matsayin gyara ya yi ƙasa da kwalabe, kwalban yana da sauƙin kwanciya yayin ciyarwa ko capping. Akasin haka idan matsayin gyara ya yi tsayi a kan kwalabe, zai dagula aikin da ya dace na ƙafafun juyi. Tabbatar cewa tsakiyar layin jigilar kaya da tsarin gyaran kwalabe suna kan layi ɗaya bayan daidaitawa.

Juya dabaran hannun A (don juya hannun ta hannaye 2 tare) don daidaita nisa tsakanin bel ɗin gyara kwalban. Don haka tsarin zai iya gyara kwalban da kyau yayin aikin latsawa.

Girman bel ɗin gyaran kwalba yawanci ana daidaita shi ta injin lif.

( Tsanaki: Mai aiki na iya daidaita tsayin bel ɗin gyara kwalban a cikin ƙaramin ƙaramin abu bayan kwance dunƙule mai hawa akan ginshiƙi na 4.)

Idan ma'aikaci yana buƙatar motsi gyara bel a cikin babban kewayon, da fatan za a daidaita matsayin bel bayan kwance screw 1 da dunƙule 2 tare, kuma idan ma'aikaci yana buƙatar daidaita tsayin bel a cikin ƙaramin kewayon, da fatan za a kwance dunƙule 1 kawai, kuma kunna maɓallin daidaitawa.

5. Daidaita sararin kwalban daidaitawa dabaran da dogo.

Ya kamata mai aiki ya canza matsayin kwalabe na daidaita dabaran da dogo lokacin maye gurbin ƙayyadaddun kwalabe. Wurin da ke tsakanin dabaran daidaita sararin samaniya da dogo ya kamata ya zama ƙasa da 2-3mm sannan diamita na kwalban. Da fatan za a tabbatar cewa tsakiyar layin isar da kayan gyaran kwalabe suna kan layi ɗaya bayan daidaitawa.

Sake daidaita dunƙule iya daidaita matsayi na kwalban sarari daidaita dabaran.

Hannun daidaitacce sako-sako yana iya daidaita faɗin layin dogo a ɓangarorin biyu na abin jigilar kaya.